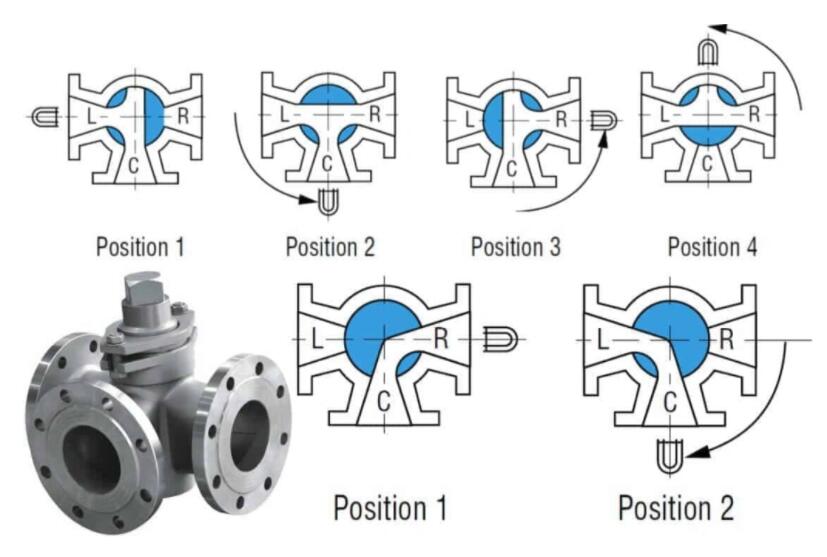

The primary characteristic of the 3 way plug valve is that it can easily adapt to the multi-channel construction, which may be separated in a three-way, four-way, etc. Multi-channel valves improve the design of pipe systems, minimize the use of the valve and some necessary connection attachments on the machines.

3 way plug valve ensures safe and effective repair without any process disruptions of redundant pressure relief systems. It is done by the smooth functioning of the valve, making it possible to switch from the primary system to the secondary system while giving the isolated system a positive shut-off.

To switch the systems through a single plug valve, just a single connection in a pressure vessel is needed so that the system may switch quickly and can avoid costly depressurizing. The valve’s basic port setup always delivers flow between the base port

and one of the side ports.

3 Way Plug Valve Application

3 Way Plug Valve is intended to manage a variety of liquids, including clean and dirty liquids, viscous and corrosive solutions, as well as sludge, abrasive and fibrous slurries. They can also handle clean and dirty corrosive gases.

3 way plug valves are used in a wide variety of applications, such as

· Flow diversion of water

· Wastewater

· Sewage and Biogas applications

· Chemical & Petrochemical

· Pulp & Paper

· Mining Power and other process industries.

·Combination of flow from different sources.

How to install the 3 Way Plug Valve?

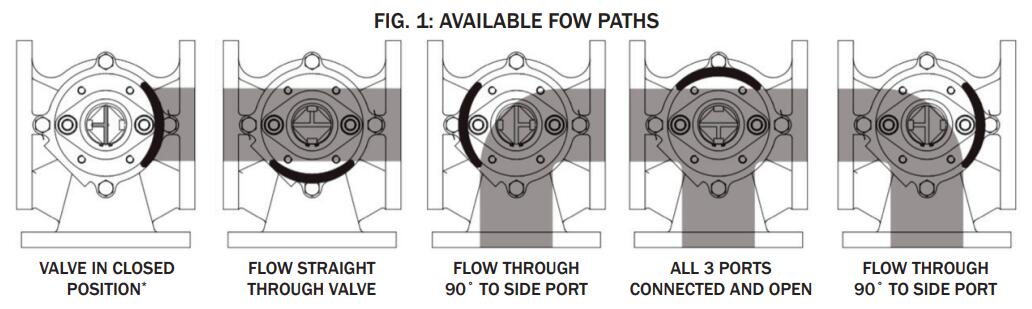

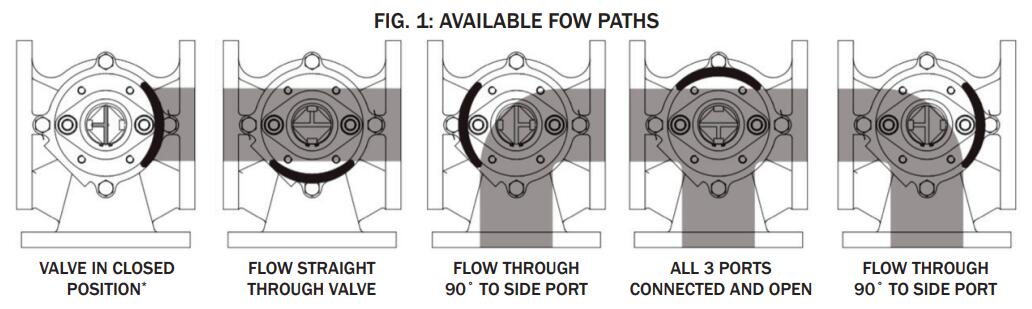

3 way plug valve can be installed in any orientation although it is advisable to have the valve stem vertical for ease of access. If the 3 way plug valve has been supplied for tight shut-off, the flow path and therefore the upstream pressure should be against the rear side of the plug (see Fig.1). The 3 way plug valve is suitable for flow in any direction although it is recommended that the valve is installed with pipeline pressure applied behind the plug with the plug face in the downstream position. 3 way plug valve must be provided with adequate support. Adjoining pipework must be supported to avoid the imposition of pipeline strains on the valve body. Heavy valves may need independent support or anchorage.

*It is advisable that the flow is against the rear side of the plug for tight shut-off applications. Not available with double-style plug.

3 way plug valve can be installed in any orientation although it is advisable to have the 3 way plug valve stem vertical for ease of access. If the 3 way plug valve has been supplied for tight shut-off, the flow path and therefore the upstream pressure should be against the rear side of the plug (see Fig.1). The 3 way plug valve is suitable for flow in any direction although it is recommended that the valve is installed with pipeline pressure applied behind the plug with the plug face in the downstream position. Valves must be provided with adequate support. Adjoining pipework must be supported to avoid the imposition of pipeline strains on the valve body. Heavy 3 way plug valves may need independent support or anchorage. Prior to installation, inspection of the body marking must be made to ensure that the correct valve is being installed.

3 way plug valve is precision manufactured items and should not be subjected to misuse such as:

• Careless handling

• Allowing dirt to enter the valve through the end ports

• Lack of cleaning both valve and system before operation

• Excessive force during bolting.

When large 3 way plug valve is provided with lifting lugs or eye bolts, these should be used to lift the valve. Immediately prior to valve installation, the pipework to which the valve is to be fastened should be checked for cleanliness and freedom from debris. All special packaging material must be removed. The mating flange (both valve and pipework flanges) should be checked for correct gasket contact face, surface finish and condition. If a condition is found which might cause leakage, no attempt to install the valve should be made until the condition has been corrected. The gaskets should be suitable for the operating conditions and maximum pressure/temperature ratings and should be checked to ensure freedom from defects or damage.

Care should be taken to provide correct alignment of the flanges being assembled. Suitable lubricant on bolt threads should be used. In assembly, bolts are tightened sequentially to make the initial contact of flanges and gaskets followed by gradual and uniform tightening in an opposite bolting sequence to avoid bending one flange relative to the other, particularly on flanges with raised faces. Parallel alignment of flanges is especially important in the case of the assembly of a valve into an existing system. The bolting must be checked for correct size, length, material and that all connection flange bolt holes are utilized. Certain sizes of 3 way plug valve has tapped bolt holes in the connecting flanges where there is no room for nuts behind the flange.