Jacketed plug valve

China jacketed plug valve manufacturer, factory and supplier, produce steam jacketed plug valve, lift jacketed plug valve, 3 way jacketed plug valve, manual,electric,pneumatic actuated jacketed plug valve and customized other jacketed plug valves with different material and standard.

Jacketed plug valve is special types of plug valve designed with heating jackets. These heating jackets contain a hot medium used to add heat to the media flowing through the plug valve to ensure the fluid viscosity remains low to avoid crystallization. Jacketed plug valve manufacturer designs these valves to operate either manually or automatically. Jacketed plug valve operates by making a quarter turn on the valve stem. The rotation of the plug helps to align the plug port to the valve ports allowing fluid flow through the valve. To close the plug valve, the plug port is aligned perpendicular to the valve ports preventing fluid flow through the valve.

Jacketed plug valve manufacturer produce various types of valves such as automatic (electric or pneumatic actuator actuated) jacketed plug valve, lubricated jacketed plug valve, non-lurbricated jacketed plug valve, lift jacketed plug valve, 3 way jacketed plug valve and others. Applications of these plug valves include food processing, coal tar processing, fertilizer manufacturing, and bitumen processing, and other highly viscous media among others. The advantages of using jacketed plug valves are versatile, fast operation, simple and compact design, easy installation and repair, high strength and zero leakage among others.

What is a jacketed plug valve?

A Jacketed plug valve is a type of valve designed with jackets meant to heat the media being transported to prevent it from crystallizing. These valves use high-temperature steam or oil on the valve body which is used to enhance the heat of the flowing media to keep it at the required state. Some of the media commonly transported through this type of valve are bitumen and liquid sulfur. Jacketed plug valve manufacturers design this valve with a cylindrical or conically shaped plug to control fluid flow. A plug is rotated inside the valve body to help open and close flow of the media. This plug is designed with a hole where fluid flows through when the valve is started. Jacketed plug valves are of simple and compact design and they are relatively cheaper compared to other valves. This valve can be operated manually or automatically.

How does a jacketed plug valve work?

Jacketed plug valve operates by turning the handwheel for a quarter turn. This rotation by the handwheel or actuator is transmitted through the stem to the plug. To open the valve, the handwheel or actuator rotates for a quarter turn (90o degrees) in the clockwise direction. This forces the stem to rotate in the same direction as it turns the valve plug. This rotation of the plug forces it to align the plug port to the valve port which then leaves the valve open for fluid flow. The fluid keeps flowing through the jacketed plug valve until when it is closed. To close the valve, the actuator or handwheel rotates in the opposite direction (counterclockwise). This aligns the plug port perpendicular to the fluid flow and thus it blocks any fluid attempting to flow through the valve.

Also, jacketed plug valve manufacturer designs this valve for throttling use in which the plug is rotated slightly to make a 45o degree turn. However, when this valve is used for throttling, it results to double pressure drop which reduces efficiency.

Types of jacketed plug valve

Lubricated jacketed plug valve

This is the jacketed plug valve that uses lubricants or sealants to ease operation over a certain range of pressure. A lubricant film is placed between the valve body and the plug to provide a lubricant seal. As such, this valve needs to be lubricated frequently according to the instructions given by the jacketed plug valve manufacturer. The lubricant used should be able to withstand the operating temperature and should not be washed away by the fluid being transported. The lubricant or seal also helps to prevent wear of parts that come into contact as well as prevent corrosion.

Non-lubricated jacketed plug valve

This is the type of jacketed plug valve that uses a non-metallic elastomeric liner or sleeve in it. The sleeve is inserted into the body cavity. The plug acts as a wedge where it pushes the sleeve on the valve body. Jacketed plug valve manufacturers use this valve to reduce friction between the body and the plug. These valves are advantageous as they need minimal maintenance, unlike the lubricated types. These valves have the advantage of having a tight shut-off and are small in size.

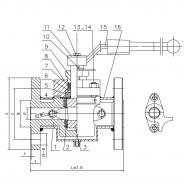

Lift jacketed plug valve

Lift Jacketed Plug Valve is applicable to the cutting and connection of pipelines medium that aroused in various industries as petroleum, chemical industry, pharmacy, chemical fertilizer, power industry etc. under nominal pressure of CLASS150-1500 LbsS, and working temperature of -29~550°C.

a. The product has reasonable structure, reliable sealing, excellent performance and beautiful appearance.

b. Opening and closing of the valve is carried out while the sealed surface is taken off so it will not cause abrasion on the sealed surface.

c. Its characteristic double-direction flow makes installation and use more convenient.

d. The materials of the parts and sizes of flanges can be reasonably configured according the actual operation condition of the requirements of the customers, so as to meet the various needs of engineering.

As for the process of opening and closing of the plug valve, when opening the valve, first of all, turn the hand wheel to make the plug lifted and separated with the sealed surface, then turn the handle by 900 to make the channel of plug to the channel of valve body, so that the valve is opened; when closing the valve, first of all, turn the handle by 900 to make the channel of plug vertical to the channel of valve body, and then turn the hand wheel to descend the plug, so that the valve is closed.

3 Way jacketed plug valve

This is a jacketed plug valve that is used in the transportation and diversion of media, which can be T port or L port design according to the flow direction.. 3 way Jacketed plug valve manufacturers design this valve to help reduce the cost of buying several shut-off valves since a single multi-port plug valve will complete the work. However, there are cases in which this valve may not shut off media flow completely. As such, a lot of care should be taken when specifying the port arrangement to enhance the right valve operation.

Automatic jacketed plug valve

This is the version of the jacketed plug valve that is operated using actuators. This plug valve is convenient for use as it does not need a valve operator to provide the torque needed to start and stop. This type of valve is also the solution in case the valve operation needs a lot of torque and frequent operation.

Jacketed plug valve manufacturers design this valve to use three types of actuators which are hydraulic, pneumatic, and electric actuators. The hydraulic actuator uses hydraulic fluid to generate the torque needed to open the valve. This type of actuator is very powerful relative to other valves due to the use of hydraulic fluid which is incompressible. The pneumatic actuator employs compressed air to turn the valve stem to open/close the valve. This type of actuator is suitable for use in applications where high levels of hygiene are demanded since the air to be used can be filtered. The electric actuator uses electrical energy to operate the valve. This type of actuator converts electrical energy to mechanical energy. This mechanical energy is in terms of torque which when applied to the valve stem the valve opens or closes as necessary.

Jacketed plug valve applications

Jacketed plug valves are used in food processing industries.

They are used in fertilizer manufacturing industries.

These plug valves are used in the transportation of molten sulfur or liquid sulfur.

Jacketed plug valves are used in bitumen processing plants.

They are used in the processing of coal tar.

Jacketed plug valves are used in other highly viscous media to ensure they are transported at the required viscosity.

Advantages and disavantage of jacketed plug valve

Advantages of jacketed plug valve

These plug valves are versatile as they are suitable for use in wide areas of industries.

They are cheaper compared to other valves like gate valves.

Jacketed plug valves operate faster as they only need a quarter turn of the plug to open or close media flow.

These plug valves can be used in both high-pressure and high-temperature applications.

They are of high strength.

Jacketed plug valves are of simple and compact design.

These valves are easy to install and repair.

Jacketed plug valves are free from fluid leakage.

These valves have a low resistance to media flow which enhances flow efficiency.

Jacketed plug valve manufacturers design these valves with few rotating parts which reduces the cost of repair due to low levels of wear.

These plug valves can be either manual or automatic.

Disadvantages of jacketed plug valve

These plug valves are not best for throttling flow since they reduce flow pressure by great margin.

Jacketed plug valve need a lot of torque to open/close due to high initial force.

Large jacketed plug valve can not be operated manually due to the large amount of torque needed.

-

( Manual, electric, pneumatic actuator is optional. )

- Port size:DN15-DN300

- Pressure: Class 150-Class 300,PN10-PN40

- Medium:W.O.G.

- Temperature:-29~150℃

- Body material:WCB, CF8,CF8M,etc.

-

( Manual, electric, pneumatic actuator is optional. )

- Port size:DN15-DN300

- Pressure: Class 150-Class 300,PN10-PN40

- Medium:W.O.G.

- Temperature:-29~150℃

- Body material:WCB, CF8,CF8M,etc.

-

( Manual, electric, pneumatic actuator is optional. )

- Port size:DN15-DN300

- Pressure: Class 150,PN10,PN16

- Medium:Corrosive service

- Temperature:-29~180℃

- Body material:WCB, CF8,CF8M Lined PTFE PFA,etc.

-

( Full port or regular port for choice )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Easy to solidify, high viscosity medium

- Temperature:-29~150℃,-40~450℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( Different structure is optional )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Liquid Sulphur, molten sulphur, etc.

- Temperature:-29~150℃,-40~450℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( Full port or regular port for choice )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Easy to solidify, high viscosity medium

- Temperature:-29~180℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( Lubricated or non-lubricated plug valve with heating jacket )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Easy crystallization medium

- Temperature:-29~150℃,-40~450℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( PTFE sleeved non-lubricated plug valve with jacket )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Easy to solidify, high viscosity medium

- Temperature:-29~180℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( We can customize the structure according to the medium )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Water,steam,oil,gas,etc.

- Temperature:-29~150℃,-40~450℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( Lubricated or non-lubricated plug valve with jacket design )

- Port size:1/2"~24" (DN15~DN600)

- Pressure: PN10-PN64 CL150-CL600

- Medium:Molten sulphur sulfur,bitumen,asphalt or others

- Temperature:-29~180℃

- Body material:WCB,CF8,CF8M,CF3,CF3M etc.

-

( Pneumatic operation:Single or double acting )

- Port size:1/2'' ~ 16''( 15mm ~ 400mm)

- Pressure: PN16 ~ 100,150LB ~ 600LB

- Medium:Easy crystallizating medium

- Temperature:-40~450℃

- Body material:WCB CF8 CF3 CF8M CF3M or others

-

( High temperature steam for jacket medium )

- Port size:1/2'' ~ 16''( 15mm ~ 400mm)

- Pressure: PN16 ~ 25 CLASS 150/300LB

- Medium:Easy crystallizating medium

- Temperature:-40~450℃

- Body material:WCB CF8 CF3 CF8M CF3M or others

-

( Full lined, Jacketed cover )

- Port size:1/2'' ~ 16''( 15mm ~ 400mm)

- Pressure: PN10 ~ PN16、 CLASS 150LB

- Medium:Corrosive medium

- Temperature:-29~180℃

- Body material:WCB CF8 CF8M+FEP/PTFE/PFA

-

( Jacket cover, lift type )

- Port size:1/2'' ~ 16''( 15mm ~ 400mm)

- Pressure: PN16 ~ 100,150LB ~ 600LB

- Medium:Water,oil,steam,gas

- Temperature:-40~450℃

- Body material:WCB CF8 CF3 CF8M CF3M or others

-

( T port or L port is optional )

- Port size:DN20~300, NPS 3/4〞~ 12〞

- Pressure: PN16 ~ 100,150LB ~ 600LB

- Medium:Easy crystallizating medium

- Temperature:-29~425℃

- Body material:WCB CF8 CF3 CF8M CF3M or others

-

( PTFE PFA Lined jacketed Structure )

- Port size:1/2'' ~ 16''( 15mm ~ 400mm)

- Pressure: PN16 ~ 25 CLASS 150/300LB

- Medium:Corrosive medium

- Temperature:-29~180℃

- Body material:WCB CF8 CF8M+FEP/PTFE/PFA