Mobile:+86-17717520739

Wechat:17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2023-05-28

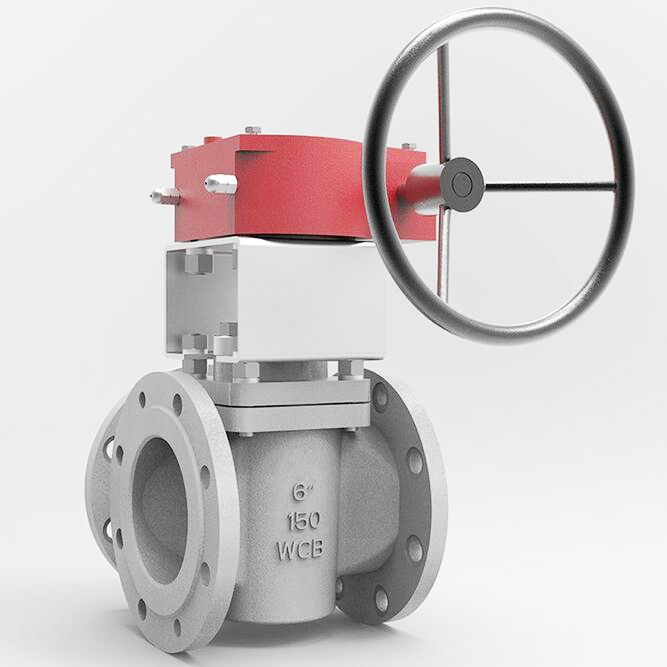

3 way plug valve working principle:

Plug valves may have multi-ports valves like three, four, or five. The three-way plug valve is the most popular multi-port plug valve.

Three ports valve is attached to pipe or tubing that provides a three-way plug valve for gas or fluid to flow through them. These ports are generally defined as one inlet and two outlet ports or one outlet or two inlet ports in the function of the valve’s flow direction.

A 3 way plug valve is quite common because it is an inexpensive and easy means of providing a single valve body with shut-off and flow control. These valves control the flow of tube control by combining the piping setup, the plug valve manual rotation, and the plug valve flow path.

The flow can be regulated using the proper type of valve and installation in ways that satisfy one or many process criteria, that includes,

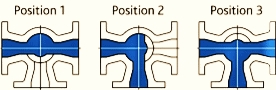

There is a basic but important internal difference in design that influences what a three-way valve can achieve. The flow or port shape pattern within the valve through the plug is this significant design distinction.

Three-way valves that generally have a third port at a right angle from the inlet are popular. The closed element is utilized to divert or combine the flow with the three-way design.

These valves can be broadly classified into the following categories:

The primary characteristic of the 3 way plug valve is that it can easily adapt to the multi-channel construction, which may be separated in a three-way, four-way, etc. Multi-channel valves improve the design of pipe systems, minimize the use of the valve and some necessary connection attachments on the machines.

Plug 3 way plug valve ensures safe and effective repair without any process disruptions of redundant pressure relief systems. It is done by the smooth functioning of the valve, making it possible to switch from the primary system to the secondary system while giving the isolated system a positive shut-off.

To switch the systems through a single valve, just a single connection in a pressure vessel is needed so that the system may switch quickly and can avoid costly depressurizing. The valve’s basic port setup always delivers flow between the base port and one of the side ports.

3 Way Plug Valve is intended to manage a variety of liquids, including clean and dirty liquids, viscous and corrosive solutions, as well as sludge, abrasive and fibrous slurries. They can also handle clean and dirty corrosive gases.

They are used in a wide variety of applications, such as